~Proven technology with numerous suction pile founded platforms installed worldwide

~Swift offshore installation a couple of hours for suction operation

~Noise free installation, no noise mitigation required

Suction Embedded Anchors (SEA) for Moorings

SPT Offshore can design and fabricate Suction Embedded Anchors for various floating structures and facilites, such as FPSO’s, FPU’s, SPARSs, SBMs, offloading buoys etc. SPT Offshore installs SEAs and complete mooring lines with a tailored Offshore Construction Vessel and/or Anchor Handling Tug. Alternatively, SPT Offshore also performs suction pile and SEA installation services from Company’s vessel(s).

Benefits of suction piles and suction embedded anchors for moorings

- Holding capacity independent of load angle.

- No external load tests required.

- Extremely high weight to holding capacity ratio.

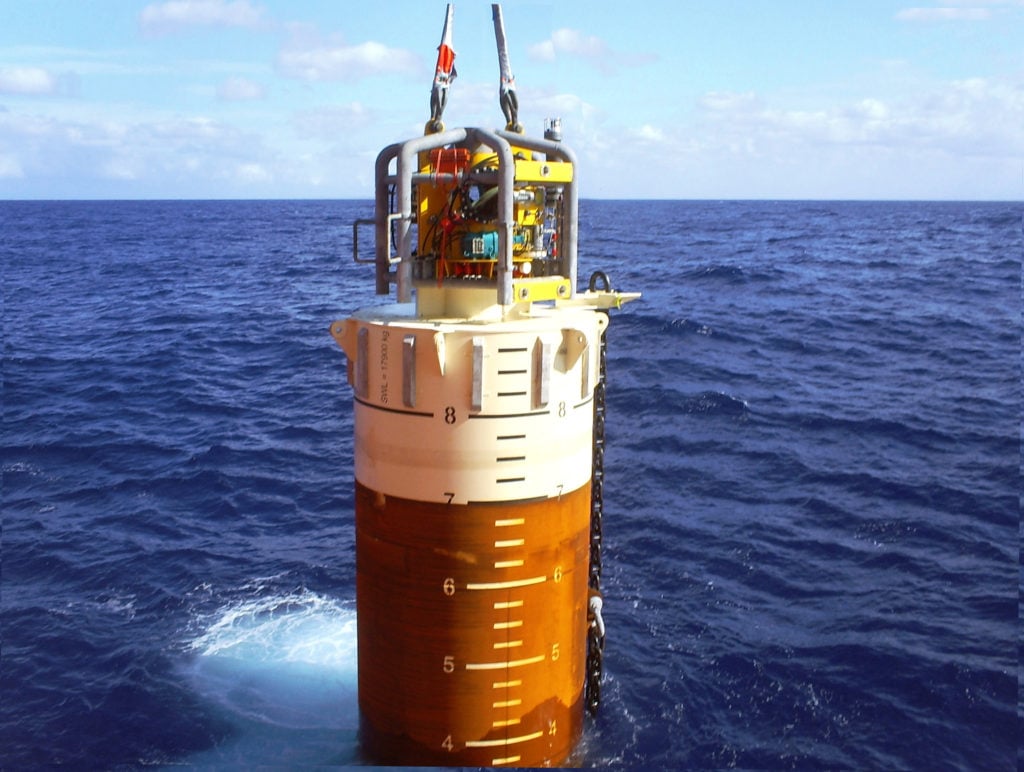

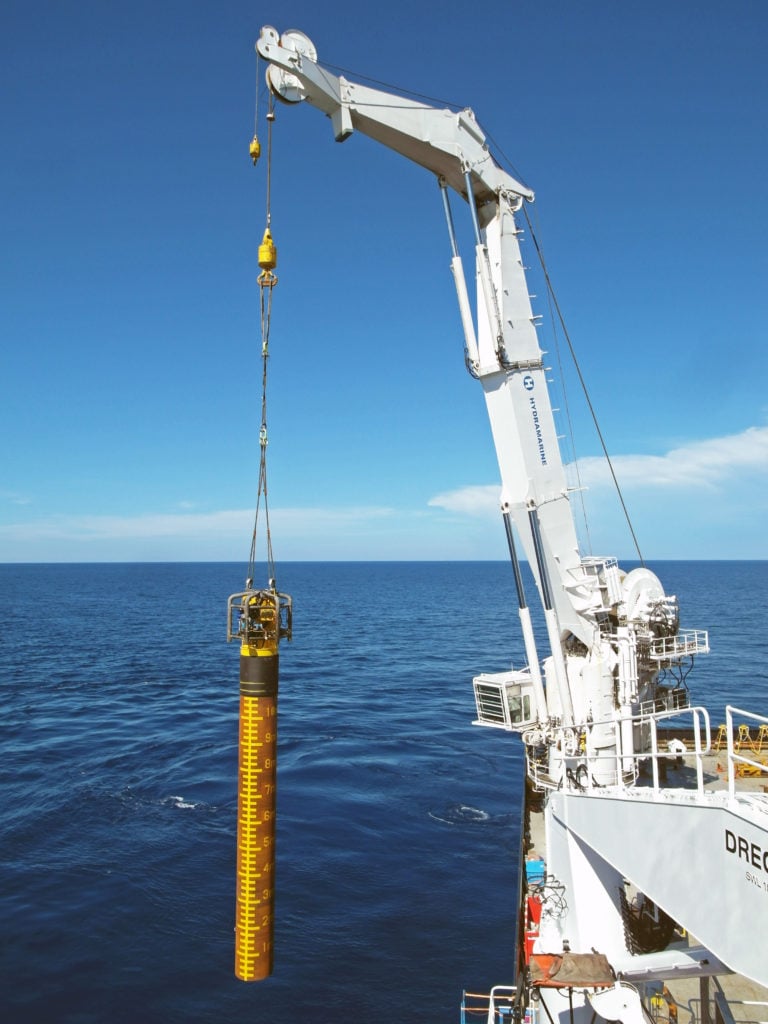

- High capacity suction pumps, reducing the critical installation time up to a factor of 5. SEA installation with SPT Offshore pumps can be done within 30 minutes.

- The SAPS-003s pump has an integrated lifting and upending frame.

- No venting required.

- Engineering and installation by one party, hence SPT Offshore takes over installation and in-situ responsibility.

Product Characteristics

- Suction pile installation to maximum of 3,000 m water depth.

- No limit on suction pile capacity.

- Suction pump lift capacity for suction piles up to 200 mT weight.

Suction piles for Pipelay Startup

If you’re looking for a quick, efficient and low cost temporary anchoring point for pipline initiation, SPT’s Offshore pumps and suction piles are the solution

Benefits of suction piles for Pipelay Startup

- Suction pile installation with SPT Offshore pumps can be done within 30 minutes.

High capacity suction pumps, reducing the critical installation time up to a factor of 5 compared to traditional installation methods. - The SAPS-008 pump has an integrated lifting and upending frame.

- No venting required, thus reducing fabrication costs of the suction pile.

- XY inclinometers integrated in the suction pump spread.

- Engineering and installation by one party, hence SPT Offshore takes over installation and in-situ responsibility.

Product Characteristics

- Several suction piles with capacities up to 275mT readily available for rental.

- Suction pile installation ot a maximum of 3,000m water depth.

- Suction pump lift capacity up to 200mT.